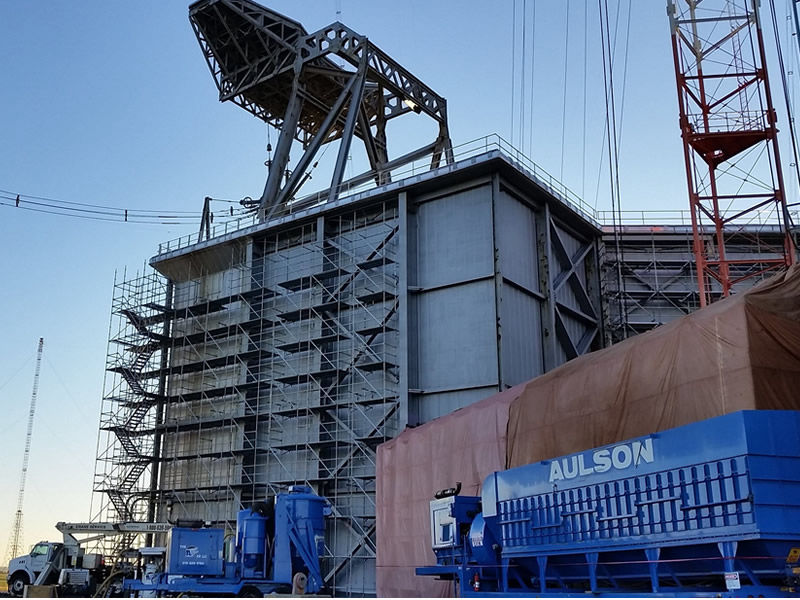

As a Contractor in the Northeast Aulson’s experience on Aged and Historic Structures was established early. As a DCAMM Certified Contractor in Historic Building Restoration, Aulson employs a combination of services to provide a turnkey resource for Historic preservation and restoration, known as the Aulson Advantage. Aulson’s early experience with lead and asbestos conditioned our crews for the performance of work on historic properties and structures to where it has become a primary focus and major service line.